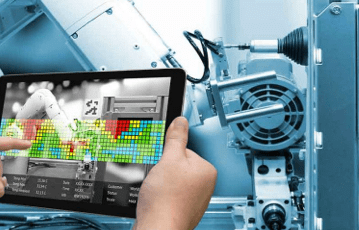

Industry 4.0 defines a ‘smart factory’ with the cyber-physical systems, the internet of things (loT), cloud computing, big data analytics, and cognitive computing as the core enablers. We build the Smart Factories to digitize lean manufacturing, overcome the traditional problem of visibility across the plant & lessen the carbon footprint.

Our Digital Manufacturing & Operations group helps clients embed intelligence into the very fabric of factories, plants, and sites. We use digital to overcome operations challenges and deliver higher productivity, throughput, and quality while reducing cost, risk, waste, and similar extemalities.

Putting intelligence into the operations of our manufacturing clients has been a critical goal. We focus on the major constituents of Industry 4.0 to create Smart Manufacturing environments. These include but not limited to Automation & Robotics, connected workers, real-time data and analytics, Quality Throughput, Higher Utilization, Flexible Manufacturing Lines, Reduced Time-to-Market, Reduced Energy Cost, Improved EHS conditions, and higher visibility across other enterprise applications.

Our team of domain and technology experts leverages existing investments to cost-effectively orchestrate OT and IT as a seamless whole that drives organizations into the future of manufacturing.A modular service offering helps manufacturers uncover and visualize continuous insights to cut costs, improve productivity, and design next-generation products. The connected factory unifies and visualizes operational data to meet changing market needs. Manufacturers can use insights from their factories to make better technology choices, cut implementation costs, and unlock value.

AIGC Smart Factory offering eliminates data siloes and creates a unified view of performance through a scalable, future-proof data platform and the digitization of physical assets. It leverages partnerships with best-of-breed internet of things (loT) media, gateways, sensors, analytics and manufacturing execution, product lifecycle, and quality management systems.

What we offer

A Manufacturing Execution System (MES) is one form of line performance monitoring system that provides live Operational Excellence KPI’s and data on smart devices and central control center and comprehensive performance reporting that allows a microlens into factory performance.

With IoT, we connect the entire operating asset vertically from shop floor to boardroom door and horizontally across the value chain from molecule to consumer, enabling 1-5% in revenue 2-6% in margin uplift.

Our cognitive & ML analytics provide predictive, real-time visibility into operational performance, potential risks, and recommended actions, resulting in reduced maintenance costs and reduced off-spec product.

Autonomous operations increase production, ensure quality, and eliminate hazardous and unsafe conditions.

We make the field workers digitally-enabled by utilizing mobility, sensors, asset tracking, analytics, and wearable technology to execute their work activities more effectively. The Digital Worker Solution leverages process and technology applications that help reduce non-productive work, create a safe work environment, automate workflows, and improve efficiencies –ultimately saving money.

AIGC Asset Performance Management (APM) solutions and services provide implementation and integration of systems such as planning and scheduling, mobility, analytics, and asset life cycle management. Condition monitoring, predictive forecasting, and reliability-centered maintenance are enabled by analytics and robotics. The firms are likely to enjoy margin expansion from lower repair and maintenance costs, lower downtime of assets, and fewer critical breakdowns.

We integrate artificial intelligence, machine learning, and sensor data to create a plant/factory “living” model that supports a physical product through its lifecycle. The digital twin helps to respond to and simulate changes, improve operations, and add value.

Case Studies