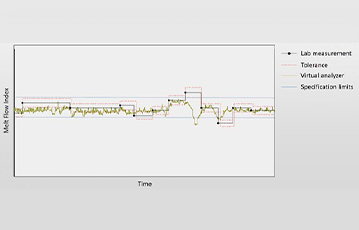

The inferential sensors or analyzers are based on models that define the relationship between the measurable variables (input) and the unmeasured variable (output). They are an essential controlled variable in Advanced Process Control (APC). These sensors are primarily utilized to better manage and optimize the product yield specifications. This leads to improved overall revenues. The majority of these inferentials use Linear Regression technology. Others utilize kinetic, heat & mass balance, and rigorous technologies.

Another inferential sensor technology that has been applied in the mainstream of data modeling is the Neural Network inferential modeling technology. This technology has been in use for over a decade now and is

Soft sensing broadly entails:

(a) Analytical techniques, which rely on using first principle models based on physical laws such as mass and energy balance and physical and chemical equilibrium calculations and utilizing suitable approximations to estimate the process parameters (b) Empirical techniques, which use available plant historical data to generate correlations using statistical regression methods, are then used to estimate and predict process parameters.

Apart from estimating the missing process parameters in a plant, soft sensing can also be used to project critical process and equipment performance parameters that cannot be directly measured in the plant. A smooth sensing system can measure real-time performance indicators such as motor and turbine driver power conversion efficiency, furnace firebox thermal efficiency, heat exchanger fouling or thermal effectiveness, pump, compressor operating efficiency, and reactor catalyst activity, etc.

We are Specialized in

Inferential and virtual analyzers started to occupy a space on replacing physical process analyzers with the trust of accuracy and repeatability. AIGC inferential analyzers are built using analytical and empirical techniques with deep statistical regression to accurately estimate process parameters

A high-fidelity, dynamic simulation model, connected to the plant data system and distributed control system can be a useful analytical soft-sensing tool. AIGC simulation model calculates all relevant process parameters and can predict parameters that are not measured in the plant. The model can also estimate equipment performance indicators such as furnace efficiency, exchanger fouling, compressor efficiency, catalyst activity, etc. in real-time, which cannot be measured using physical instrumentation.

The simulator will also have an auto tuning module, which will ensure the simulation model remains current with changing plant conditions and replicates the natural process at all times.