Everyday objects made intelligent with the addition of computing power and made connected to the Internet, to form the Internet of Things (IoT) are what we call ‘Smart Devices’. Smart devices gather and share data from the edge of the network, and while they may be small or may come in many sizes, they can be powerful tools in the current edge of Industry 4.0.

They range from small asset tracking devices to wearables that monitor health, wearables that help visualization of remote facilities or intricate sub-components, to connected refrigerators and other smart home components. They range from industrial usage to home appliances. Smart devices use sensors to gather physical data, such as light, temperature, and presence, and deliver that data to be analyzed and used to provide valuable insights to users.

We are Specialized in

AIGC and its partners provide state-of-the-art personal and industrial devices equipped with edge-computing capabilities. We have aerial drones and mobile robots with their own edge-processors to perform on-the-edge tasks with low latency and even AI-driven tasks such as object recognition or avoiding obstacles. Cloud-computing also has been a key platform for our IoT and our smart devices for quite some time. Some analytical tools for decision-making processes on-the-edge can be done on the cloud to spread out computational loads from the edge-processors.

Our smart devices, intelligent IoTs and sensors are connected in many ways depending on the client’s need, types of data transfer, power consumption, data size, speed and frequency of transmission, latency and so on. It covers as well both Industrial and non industrial applications. It ranges from satellite-com, to the most advanced cellular type of LTE (4G, 5G), to wireless WIFI6, Bluetooth, to the low-power LPWAN such as NB-IoT, LoRaWAN, Sigfox, BLE and so on. These advanced connectivity options are very instrumental in complementing our smart device applications.

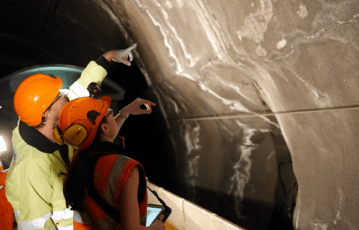

The experts in AIGC understand very well the need for smart devices such as mobility tablet to facilitate hands-on industrial tasks. Most tablets in the market do not conform to the harsh and some extreme environment. AIGC provides the best-in-class, intrinsically safe and market-proven industrial tablets for use in any industries that require rugged and safety-conformant product.

One of the most important elements in perfecting our state-of-the-art solutions is computer and machine vision. The experts in AIGC understand the crucial need in specifying the right vision system for the application. This can be in the matter of equipping our autonomous UAV (unmanned aerial vehicle, or aerial drones) with the best resolution computer vision cameras, or in specifying the correct rugged industrial machine vision system for our industrial robotics and automation systems, or even in selecting the intrinsically safe vision system for oil and gas zone1 application.

Thermal and infrared imaging are becoming increasingly popular across many industries as companies started to realize the importance of identifying potential defects and failures in early stage well before any catastrophe or major shutdown happens. AIGC offers a variety of easy-to-deploy, rapid temperature screening solutions that can help companies protect their assets, critical equipment, human workforce and avoid unexpected downtime. Our cameras range from the basic un-cooled handheld version up to the most sophisticated and ultra-sensitive ‘cryo-cooled’ version to meet the most demanding requirements from clients.

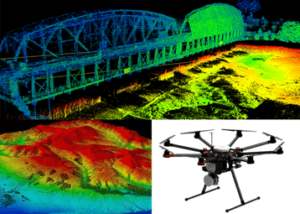

Laser scan and Laser light detection and ranging (LiDAR) are becoming more in-demand since the advancement of autonomous systems, smarter robotics, autonomous delivery solutions, smart navigation, terrain and infrastructure mapping, and also Digital Twin applications. These include AIGC’s solutions for autonomous ground robots’ path-finding, near-object sensing, object detection and obstacle avoidance. LiDAR is also equipped to some of our UAVs for application in 3D mapping of terrain and infrastructure. In the case of underground tunnel inspection and even underground mining activity, our LiDAR can also provide the best 3D mapping solution to get the best accurate results for the clients. Our ground laser scanners are capable of capturing any object desired whether for processing plant facility or a complex shape equipment for digital twinning.

Our company provides smart, powerful Laser Scan & LiDAR solutions ranging from basic close-range sensing solution, up to the most advanced long-range, multi-return, high-resolution and accuracy specifications for the most demanding requirements.

Our team of experts in AIGC came from various industry backgrounds and therefore have dealt with many types of asset inspection and equipment monitoring activities within such as oil and gas industry, chemical industry, power generation and distribution, telecommunication services, construction and many others. We understand very well the need for some non-intrusive and non-destructive inspection activities. Therefore, AIGC and its partners worked together to offer comprehensive solutions that cover wide spectrum of inspection requirements covering various types of corrosion defect, fatigue, creep, cracks & propagation, fiber fracture, stress concentration, welding joints, and so on. Our solutions range from traditional to the most advanced options:

- Ultrasonic Testing

- Acoustic Emission

- Magnetic Particle

- Automated Ultrasonics

- Digital Radiography

- Pulsed Eddy Current

- Ground Penetrating Radar, and many more.

Case Studies