Shaping the future of manufacturing via 3D Printing

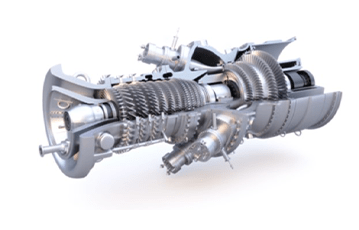

3D printing is an additive process of building objects, layer upon layer, from 3D model data instead of subtractive manufacturing methodologies like machining. 3D printing helps create intricate designs that are difficult to make through traditional methods, saves enormous amounts of time during product design and development stages, and eliminates scrap. There are multiple processes developed for 3D printing.

The 3D printing technologies are grouped into seven categories based on fundamental elements of the machine’s functionality; Metal Extrusion, Material Jetting, Binder Jetting, Vat Photopolymerization, Sheet Lamination, Powder Bed Fusion, and Directed Energy Deposition. The maturity of these technologies ranges from concept designs to mass production.Additive manufacturing and 3D printing can improve customer service, speed time to market, reduce distribution costs, and enable mass customization by allowing local subcontractors—or even customers—to create components using onsite printers, using designs licensed by a manufacturer. It can also reduce environmental waste by recycling old products into the raw material for new printed products.

The 3D printing ecosystem consists of several aspects, including scanning, software, and service bureaus. At AIGC, we have committed to investing in the very best equipment, capabilities, facilities, and people. We have an unparalleled global partner of 3D printing capabilities and an experienced team to design and manufacture. Calling on our unique knowledge resources and experience can accelerate your progress through the technology and manufacturing readiness levels to bring your product to market faster.

What we offer

AIGC additive manufacturing extends to metal parts 3D printing. Our goal in selecting from our extensive 3D printing options to meet the requirements of each unique application. We are machine agnostic and work with our customers to provide the best solution in our growing offering as we scale to meet our customers’ needs.

Creating new solutions to your manufacturing challenges. Our expertise helps our customers overcome even the most demanding design needs, whatever their industry, and whatever the application. We welcome the challenges as an opportunity to leverage our experience in additive manufacturing and bring a new component to the market. We will work with you to provide a solution – and we believe that if you can imagine it, we can build it.

We use Computer-Aided Design (CAD) support with all major software packages to help in the custom design process.

Topology uses optimization to reduce component weight and optimize structures for performance and manufacturing methods. Our guidance in design for post-processing and topology optimization offers our customers the most cost-effective solution to meet each design requirement. AIGC expertise range from prototyping and tooling for transport and the general industry in advanced manufacturing of industrial equipment. They can help customers navigate the requirements of AS9100, NADCAP, ITAR, ISO 13485 during part and process certification in AM.

Case Studies